Photon Mono SE Slimeer Settings. Lower layers

Photopolymer printing: 10 slice settings to achieve the best results

3D printing on photopolymer printers has become more affordable due to a decrease in prices. New printers of printers are more and more often produced, and many consider the possibility of using a photopolymer printer for their projects.

Small printing provides the best surface quality than FDM printing, and is great for miniatures and figurines, where the smallest details are of great importance. But if you want to use all the advantages of photopolymer printing, you need to know the correct settings of the slice to get the best results.

In this article we will discuss some of the most important settings of the slice that you should know. Although there are other resin-based printing technologies, as well as other slisers and approaches, we will consider the topic specifically on LCD technologies and printing settings available in the Chitubox slice. However, before moving on to settings, let’s look at how to print on the basis of liquid crystal screens differs from other technologies of photopolymer printing.

Comparison of technology

3D printing on the resin is performed by influencing the photopolymer material of the light source for its curing. In addition to photopolymer printers based on liquid crystal displays, there are two other main types: stereolithographic (SLA) and 3D printer with digital light processing (DLP). All three technologies differ among themselves methods.

SLA-Probage uses a laser as a light source for curing resin, sequentially highlighting each pixel in the layer. This was the first invented type of printing with resin, as well as the first 3D printing method in history. These printers provide exceptional quality and are often used in high-quality 3D applications.

DLP printers use a UV projector instead of a laser as a light source to cure resin. Directed through a complex system of mirrors, the projector simultaneously lights a whole layer, which does it faster than the SLA printer laser.

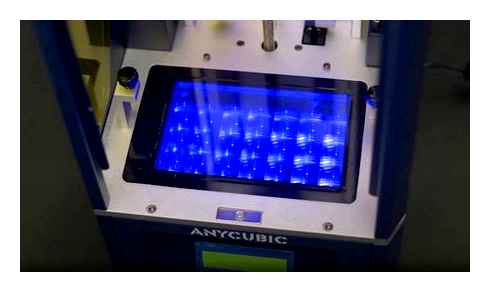

3D printers based on liquid crystalline displays are somewhat similar to DLP printers in the sense that they also light the entire layer at once. They differ in that the light passes through the liquid crystal screen, which masks certain areas, selectively allowing the light to pass through certain areas of the screen. Therefore, these printers are also called printers with “disguised SLA” (MSLA). LCD printers are relatively cheap, and most 3D printer for hobbies, such as Anycubic Photon and the Elegoo Mars series, use the liquid crystal technology of layer lighting.

We use Cura on 3D SLA Photon Printer

As it happens, I decided to study the new 3D printing technologies and bought a 3D SLA PHOTON printer, but his software, namely, the slider leaves much to be desired, it is very weak. No control of filling, support is poorly controlled, and.P in general, I decided to get around this business with the help of Cura, I just decided that it might work and you can make it I looked on the network description of the Photon format, it turned out to be quite simple And this is what came of it: it came out:

While I was looking for me to create all the management from scratch, but after I found the Photon File Editor project that has already been implementing a lot and I decided that we would just create a converter with Gcode in the set of images that can be used after this project.

Understanding the Gcode quickly painted the program, this is the case, printed a couple of models ok. I decided to share with you the result of my work.

The step initially needs to create a new printer with parameters:

Step after indicate the height of the layer z = 0.05 and wall thickness = 0.047:

Step 1. Cut into layers, see something like this:

You can make sure that everything was cut correctly and the filling is correct:

Problems with Anycubic Mono and Mono-X Prints and How to Fix Them

Step Stop the script indicating him gcode

Step 1. If everything is good, you can see the process of work:

Step 2. All layers will be saved in their own files /Layers /Layer_xxxxxxx.PNG

Step in the editing menu of “Edit” Choose to import pictures “Import Bitmaps”:

Step select the catalog in which there are files with the image of the layers:

Step enjoy the work done and apply our settings

If that, so that every time you do not change, you can correct the file with the premiums lying in the Photonfileeditor/Resources/Resins catalog.TXT

The final result will be the use of the usual slice and reducing the final weight of the model. For example, a model with complete filling and dimensions: x = 2.9mm y = 4.5mm z = 7.3mm weighs 43 grams, while the model increased by 70% with 5% filling the chicken and dimensions x = 4.93mm y = 7.6mm z = 12.41mm weighs only 51g. Total we get that the size is 70% more but the weight is only 19%. I think this will help many save on so not a cheap resin Yes, and use the usual software like Cura is also pleasant ^_ ^

The final seal took place with the settings of 1 second, the screen was turned off and 7 seconds of light.

Model with full filling and dimensions: x = 2.9mm y = 4.5mm z = 7.3mm weight 43g

Model with 5% filling the chicken and dimensions x = 4.93mm y = 7.6mm z = 12.41mm weight 51g

But there is an bad place if the model has too “thin walls”, then the internal mesh of the filling will be noticeable:

Of the dependencies, the Gcode2photon converter is only Python-Pil, works on python 2 and 3 versions.

I myself use GNU/Linux, so if you need more detailed information on the launch of Windows, I can describe this business;)

Anycubic Photon Mono X: A Brief Review

Anycubic Photon Mono X. A compact and inexpensive printer that is suitable for solving different problems (from the implementation of DIY projects to training and help in a small business). This monochrome LCD printer with a 4K matrix has the largest area of construction in the Anycibic Photon Mono line. Print volume is 192x120x250 mm.

The equipment has an LCD matrix and a 8.9.inch diagonal screen, which allows you to speed up 3D printing 3 times compared to other technologies. The built-in Wi-Fi module makes it possible to remove the Internet and print.

Software

The printer comes with built.in software Photon Workshop V2.one.24 RC7, which allows you to quickly prepare 3D models for printing. The only negative of this program. pre.installed settings from the manufacturer that cannot be changed.

To prepare files, you can use a more convenient chitubox slider. It allows you to choose a printer profile or create a new one, as well as set the parameters of the polymer used. Data does not need to be entered again. They are automatically preserved.

Anycubic Photon Mono SE Review: A reliable and fast polymer 3D printer

Monochrome high-speed LCD printer

Photon Mono SE is equipped with a monochrome LCD matrix. This new matrix is more wear.resistant and durable than traditional, its declared service life is 2000 hours. It has increased transparency, which in combination with a more powerful LED radiation source reduces the time of curing the layers.

In the case of Photon Mono SE, a monochrome LCD matrix infuriates speed up to 80 mm per hour.

Quickly. but not to the detriment of quality

Photon Mono Se axis has double guides, which prevents fluctuations, increases accuracy and does not allow the printer to swing during operation.

This, accordingly, leads to an impressive print quality and smooth surfaces with intricate details. a result that could be expected from a much more expensive machine.

Photon Mono SE has a “matrix parallel light source”, which provides uniform distribution of radiation energy over the area and increasing the accuracy of printing. The thickness of the layer is less than 50 microns. Prints are obtained quite detailed so that they can use, for example, some dental offices or even jewelers (for modeling).

What we have?

Plastic bath for polymer with risks

Photon Mono marks the new field of Anycubic, the first wave of monochrome MSLA printer. Such a technology, when a mask from the LCD-VedioDDs is more effective between the UV emitter and the photopolymer than RGB LCD. The speed of curing is higher, the seal is noticeably faster, and the operating time of the ultraviolet source is much less.

This is no longer a wonderful new world, most MSLA printers, which are worth looking at today, work just like that. Then what is the secret of Photon Mono?

Function

The main feature of Photon Mono is a monochrome matrix, which, as we have already said, increases the print speed. Standard polymers turn away in about 2 seconds.

As now, it seems, it happens with all the polymer printers of Anycubic, the company supplies devices with a test sample to determine the time of curing, which helps to tune in to the optimal speed with high detail. So it should have been with all the printers. But no. So let’s give Anycubic.

When unpacking, Photon Mono setting up and working with it there are no difficulties. Unless he sits very tightly in his foam bed in which he comes. The kit also includes a cord and a power supply (12-volt brick, like laptops) and a lot of accessories than Anycubic also pleases.

The printing platform has a slope so that the remnants of the polymer flow out from it. laudable accuracy

To align the print platform, you need to remove the bath for the polymer, loosen four bolts, put a sheet of paper on the matrix and lower the platform on it. Press the platform so that everything is even, tighten the bolts. and all the things. This is, in fact, a standard procedure for MSLA printers.

In principle, Photon Mono Anycubic is all the same worthy standard installed for the Photon line back in 2018, but with hardware updates that go beyond a simple upgrade to a monochrome matrix. Our lines are smoothed out here, the design has been changed, it became just pleasant to work with the device.

In the system of movement along the Z axis, we see the transition from the rods to the linear guide, which theoretically should make the printer more stable and accurate vertically. Almost so it is. If we take vertical default settings, exceptionally clean prints are obtained almost without stripes and other artifacts on Z.

Single linear guide running screw in Photon Mono

Print quality when using standard profiles and an excellent stock polymer, as expected, excellent. We managed to make several incredible printouts on Photon Mono almost without any efforts. There is a feeling that Mono forgives mistakes. this is what we liked so much in Elegoo Mars and the original Phrozen Sonic mini.

It seems that for this it is worth thanks very worthy default settings for Z. When changing the layer, Mono is in a hurry.

The form

Start with the fact that Anycubic Photon Mono is a neat small printer. Its plastic case sits tightly on the table, and the UV-blocker cover is rising and removed, providing access to the bath for the polymer and print platform. Such a realization, it seems to us, is much more convenient than a hinged door for printers of this size and at the upgrades Photon and Photon S (as well as the newer Photon Mono SE).

Decorative protrusions around the perimeter of the base of the machine look neat, but they are waiting for a random drop of polymer to become sloppy; And then it is difficult to clean up annoyingly.

Like all the previous Photon printers, the USB port is located on the side, closer to the rear, t.e., To use it, you need a lot of free space. Back in 2019, we reported for this Elegoo Mars, but the lesson did not go for the future. Photon Mono SE The same trouble.

Power switch and USB port on the right

The novelty of Photon Mono is a completely plastic bath for polymer, that many could count for lowering the rating. Such baths often become an object of criticism, although a decisive role is played by a compromise between strength and resistance to mixed polymers. By and large, the metal exceeds the plastic for those materials that we are most often using, it looks better. but this is a somewhat biased opinion, including in relation to Photon Mono.

In practice, as in the case of Phrozen Sonic mini, when it was supplied with a plastic bath (no longer supplied), it was in order for about 100 hours of work, so there is no particular problem here. The printer owners will work with him much longer, so we can only offer that everything is in order in the short term.

One thing that we will not discuss so hotly so far is that FEP film is already pre.clamped in an unusable stretch plate. As far as we can judge, without getting down to hacking this thing, the replacement of FEP, apparently, will require purchases of a special node from Anycubic, and not the film that you like.

6-inch mono-LCD matrix Photon Mono, a three-month warranty applies to it (as indicated on the Anycubic website)

Despite the cost of reduction in the bath, Anycubic tried to overcome one of the stumbling stones of the most budget polymer printers. the leakage of the polymer residues to the print platform. This happens in Anycubic Photon Zero with its experimental starting dumping price of 139; Sonic mini Phroozen, another budget attempt, also has this problem. Not with Photon Mono, in which the platform has a slope that allows you to drain the excess polymer. Wonderful.

Verdict

Among the large carriers of 4K Mono X, two.year.old metal structures, all the variations of Mono SE, the innovative budget printers of Phrozen and the recent efforts of Elegoo Mono. Anycubic Photon Mono feels a little lost. He has few distinctive features, except for the rapid curing of the layer, which is no longer considered a distinctive feature.

But it cannot be said that this is a bad printer. He is not bad. He prints thin details very well, and his native program Photon Workshop, which at first disappointed us so at first, is gradually improving.

In general, Mono is a decent, albeit boring printer that can work quickly. He, of course, is not the worst representative of the polymer press, but the requested price will make you think twice.

Annycubic Photon S is a new version of the popular 3D printer that entered the market in early 2019. The model was doomed to success, as it took all the advantages from the first “photon”, while the print quality of the press has grown significantly.

The new photon is made of plastic, unlike the previous version. The manufacturer substantiated this step by reducing production. S-ka acquired a more productive filling, so the metal case would add several thousand to the final cost of several thousand. He would cease to be perceived as “folk”.

- Wavelength UV 405 Nm

- Light source UV-Led

- Printing LCD

- Printing permit 25601440

- Press accuracy XY: 47 μm, Z: 1.25 μm

- The area of the working chamber is 115x65x165 mm

- Speed 20 mm/h

- Layer thickness from 25 μm

- 2,8.colored tft display

The handle in the ANYCUBIC Photon S is made in the form of a “ears” in the bottom of the door. There are no side pens. Sight glasses became larger. The main nests for connecting power, as well as USB-sides, remained in old places.

Inside the apparatus now two hoods at once to eliminate an unpleasant odor. In special compartments, there are two conclusions on the sides of the working chamber, in which there are activated coal bags. The ventilation system itself has undergone changes. This is visible on the back cover of the device.

Interesting! Some network users have tested new ventilation. From their words it became clear that there are improvements, but they are insignificant. For better cleaning of passing air, you need to put more productive carbon filters.

Important change that touched the guide axis z. Now an optical ending is installed on it, and the working platform itself moves along the two guides. This helps to reduce backlash and vobbing. The working area of the construction of the device has also increased. It has become more than 10 mm. A pleasant trifle.

Important! The fastening of the working platform is in the lower position when the user opens the printer “from the box”. To install the platform, you need to turn on the device in place, and then raise the fasteners by 100 mm through the system menu.

The size of the main display has not changed, although the manufacturer has slightly processed the menu design and changed the color palette. The photon also got rid of the “illness” of the younger counterpart. On some models of the first “photons” the screen did not want to work if a flash drive was not inserted into the device. This mistake was corrected.

One of the most important innovations is the printed matrix. The device has a new UV matrix, in which 28 diodes are installed, against 4 in the younger model. The flavor power has increased by 10 watts. over, positioning on the axes remained the same. But the quality and detail of ready.made models has increased significantly. This is noted by many users and printers.

The main characteristics of the ANYCUBIC Photon S:

- Basic energy consumption: 40 watts;

- Dimensions of the device: 230 mm × 200 mm × 400 mm;

- mass (without a box), kg: 5.9 kg

- Working on: Photon S Workshop;

- The wavelength of UV: 405 Nm;

- The dimensions of the working chamber: 115 mm × 65 mm × 165 mm;

- Resolution: 2560 × 1440 points;

- Technology: LCD;

- The thickness of the printed layer from: 10 microns;

- Accuracy: XY: 47 μm, Z: 1.25 μm;

- Monitor: 2.8 “Color TFT;

- nests: usb;

- Speed: 20 mm/h.

Pros and cons

Alcubic has already managed to gain popularity both among experienced printers and newcomers. Each of them noted the positive and negative sides of the device. We will analyze the most common advantages that users noted:

- The accuracy of detailing and printing “from the box”. You can unpack the device, make the primary calibration of the platform and start printing. Without long torment with profiles.

- Despite the fact that the device case is made of plastic, the design itself and the frame turned out to be rather strict.

- Thanks to the new Paraled technology, it was possible to reduce the parasitic light. Distortions along the edges of the field have practically disappeared.

- A fairly simple print process and fast printer setup mode. This was noted by all the owners who previously worked on FDM.

- Low price compared to competitors.

- Despite the enhanced ventilation, the printer is still decently “smacks”. Forced ventilation of the room is necessary, especially if you are printing in a living room.

- Pretty flimsy door. You need to understand, in this case we are talking about a plastic door, but not about the design of the printer itself.

- High cost of polymers. This minus applies to all photopolymer printers.

- The device works only with its own file extensions. However, many 3D printers sin by this.

- Small size of the printed model.

But these disadvantages cannot cross out all the advantages of this apparatus. over, the accuracy of the print allows you to use it in different fields of activity.

The difference between Anycubic Photon Mono, Mono Se and Mono X

It was not so long ago, when Anycubic has released its first budget polymer 3D printer-Anycubic Photon. In 2018, he, of course, became a sensation, a breakthrough-such a powerful polymer printer, only a little more expensive than the usual budget FDM apparatus. Today, only two years later, the technologies have become noticeably more developed, the curing time of the layer has decreased, the details became thinner, the working volumes are larger, and in general the polymer table printer has become a more relevant choice. And all this helped to launch Photon.

After the next Photon S model, Photon Zero was released in Anycubic. a budget polymer printer for beginners, which surprised at the cost, but, alas, due to the quality. Now, when monochrome matrices with a resolution of 4K became the new norm, Anycubic has offered three new Photon Mono, Photon Mono Se and Photon Mono X line printer.

In order to understand which of the options is better for you, we offer them to compare them.

Generally

Resolution of the matrix, pixels

Layer curing time, seconds

Max. print speed, mm/h

Permission

Resolution-one of the key parameters of any 3D printer, especially polymer. LCD (LCD, LCD) matrix are components that form permission, acting as a mask for the radiation source.

Two of the three printers that we are considering here. Anycubic Photon Mono and Mono SE. have a 2K, 2560 × 1620 pixel matrix. Their working volumes are identical (Photon Mono offers 5 mm more along the Z axis, but this is not related to permission), the XY permissance is 51 microns (0.051 mm).

Anycubic Photon Mono X Matrix with higher resolution, 4K, 3840 × 2400 pixels. This, however, is effectively compensated by a much larger print area-192 × 120 mm, and the XY resolution is 51 microns (0.051 mm), like lesser brothers and sisters.

All three cars give out layers up to 10 microns thick, guaranteeing exclusively detailed prints.

Design and design

If you do not take into account the working volume, here we have, perhaps, the most noticeable difference between three printers. At least this applies to Photon Mono SE, which preserved the original design of the Photon series, which distinguishes a compact solution of the lid and the door opening upward. With Photon Mono and Mono X, Anycubic decided to follow the path that really became the most fruitful designer choice for budget polymer printers: this is a removable acrylic cover.

Another difference was found on the PHOTON SE print platform. there is only one screw for alignment instead of four, like Mono and Mono X. This is a trifle, but it makes life a little easier, and if alignment annoys you in principle, it will become a big plus in favor of SE.

As always, regarding the appearance, everything comes down to personal tastes, but from the point of view of convenience of use, free access to the workspace makes the situation a little easier. Mono and Mono X create a slightly more budget atmosphere, which is generally harmonious, because the seal by polymers can literally be dirty.

Inte Wees

Each of the PHOTON MONO printers under consideration has a USB-it would be strange if it were wrong (Mono Se and Mono X also have Wi-Fi modules). It is available in stock, but using it is not so easy. To do this, you need a special Anycubic application that lives on a flash drive in the form of a file.APK. Not the most practical way to distribute programs for smartphones, especially when you consider that there are no smartphones with the USB Type A connector in the world. Having hardly recovered from shock, we scored in Google “Anycubic App” and found a page on the Anycubic website, from where the application can be downloaded from (so that it can be installed bypassing security settings). Well, vanity!

And the application is available only for Android devices, so if you have iPhone, then you are not lucky.

Working volume

You do not need to be a genius to understand that Photon Mono X has the largest working volume here. But first about those who are smaller. Photon Mono offers 1.72 liters of print volume, slightly superior to Photon Mono SE, which has 1.66 liters. According to the axes X and Y in both cases, everything is the same (both the same print platform), only Mono half a centimeter higher.

But Mono X has as many as 5.65 liters. almost three times more than Mono and Mono SE. In other words, it should have more than enough space for all your ideas.

Smell

One of the advantages of Mono SE is the presence of built.in filters with activated coal. The original Photon did not have filters, Photon S. two, in the rear of the device, the Photon Mono SE also has two and in the same superstructure. That here is the new one is fans installed over filters, which promises an active struggle with such an undesirable side effect of polymer printing as a strong smell. By posting filters outside the closed lower part of the case, Anycubic, as it were, hints that they need to be changed (they are stood), but we cannot say how easy it will be. Mono and Mono X described advantages, t.e. filters, no.

Press speed

All three devices under consideration of the monochrome matrix. hence the Mono in the title. Such matrices compared to non.monochrome. allow you to significantly reduce curing time from about 8 seconds to 1–2. Even the best matrix in terms of the quality of the final result has a limit. this is the power of the radiation source that passes through it, and this is directly related to the speed of print. The Photon Mono SE has a more powerful source than Mono, so in one case the speed reaches 50 mm/h, in the other. 80 mm/h.

Mono X, although it probably has the most powerful source of radiation among the three devices under consideration, gives out 60 mm/h-due to the larger print area. This is still pretty fast for such sizes.

And, perhaps, the most significant difference between these budgetary fortresses is the price. Photon Mono is the most affordable and worthy competitor to other budget polymer printers such as Mars Pro or Crealy LD-002H. Anycubic Photon Mono SE with its convenient functions and a higher print speed is a little more expensive. These functions are in t.h. The filtering system, very good. Good. but we will not exaggerate. The largest of the trinity, Mono X, is the most expensive, and here some difficulties arise in the process of comparing.

Recommended settings for 3D printing with photopolymena resin Anycubic

One of the most frequent questions that our buyers arise when buying Anycubic resin is a request for the parameters of the slice settings to obtain the highest quality result when printing on LCD or DLP 3D printer.

First you need to figure out which slice you prepare a control program for a 3D printer. If you work on Anycubic equipment, and use the standard software from Anycubic as a slider, then most likely all the necessary settings for the original tar will be found in the program from the manufacturer itself.

If you use 3D printers from another manufacturer or other software to prepare a management program, then we recommend the following settings as standard settings:

| Layer height (mm) | Layer light time (sec) | Power (%) | Note |

| 0.05 | 3 | 60 | Less speed |

| 0.025 | 2.2 | 60 |

Actual for resin Anycubic Basic, Anycubic Eco, Anycubic Craftsman.

I would like to note that such parameters are a certain average solution that was found due to our own production and reviews of customers, which we collected together to write this post.

Attention! We draw your attention to the fact that Anycubic resin has quite specific smell. The resin has acrylic. When working with resin, it is necessary to work in a well.ventilated room and have a protection of the respiratory system!

And what settings do you have in the maximum print quality? Write in the Комментарии и мнения владельцев to collect the most effective parameters for those in need!

Examples of print

We align the platform before the seal. This is done very easily according to the instructions. Then we install the bath and fill in the resin. Several warnings at once: do not take the bath from below, it is better not to touch the film with your fingers at all; Before pouring the resin, it must be shaken well.

For printed, I used a gray.colored photopolymer resin from eryone. (very soon there will be a review on her). The first test model. Value values by default: 45C for the first 6 layers and 2C for the rest, a layer of 50 microns. I look at the model alive and try to find layers, but they are not visible, it is like a cast. This is very cool. The model looks just cast.

Perfect Resin 3D Prints | Exposure Calibration Testing

This is the second test model supplied on a flash drive with a printer. In general, it is part of a whole test model, because there are such 8pcs immediately and with different light overlight: from 0.8C to 3.6s. In general, for my resin, the recommended time of lighting is 2 seconds. Some of the needles accidentally broke his finger ((at the very division they were there.

I really wanted to print the baby Yoda (I think the majority watched the Mandaloret series). Highlighting the first layers of 22C, subsequent. 2C. This model printed with support. Perhaps it was necessary to print it immediately on the platform, without lower supports, but so far I only master this printing technology. I washed the resin simply with water from under the tap, apparently not everything washed away and in the process of deducing the model partially turned white. Most likely it was necessary to use a soft brush for better washing. A model of only 35mm high was very detailed. In the future, I will paint it with acrylic paints.

The wife painted and here is the result.

If the contact of the model and print platform is large, it is quite difficult to tear off the models. During printing, you can change the time of lighting, print speed and other parameters.

Since I also have FDM printers, the first thing I printed the lid for the bath and mount for draining the resin from the print platform. This is what the mount looks like.

And this is a lid for the bath.

I would like to hear the advice of experienced printers on the correct location of the model on the platform. I also read somewhere that it is not necessary to drain the resin every time, this should only be done when changing the resin to another. Therefore, I did so, after printing I do not drain the resin, but just cover the bath with a lid and that’s it. If the printer is idle for several days, then before the subsequent seal, I just mix the tar in the bath with a plastic spatula and start the seal.

The printer is very good. Honestly, I did not expect such a print quality. A couple of minutes of settings and you can already start work. The assembly of the printer is high.quality, everything is done at a high level. The only thing, I would very much like the rubberized legs. Monochrome 2K display provides much faster printing compared to the usual. I will safely recommend for the purchase. Now I’ll start printing figures to order 🙂

Product for writing a review is provided with a store. The review is published in accordance with P.18 Rules of the site.